Preventing microplastic release from textiles

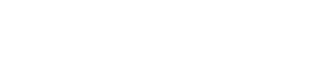

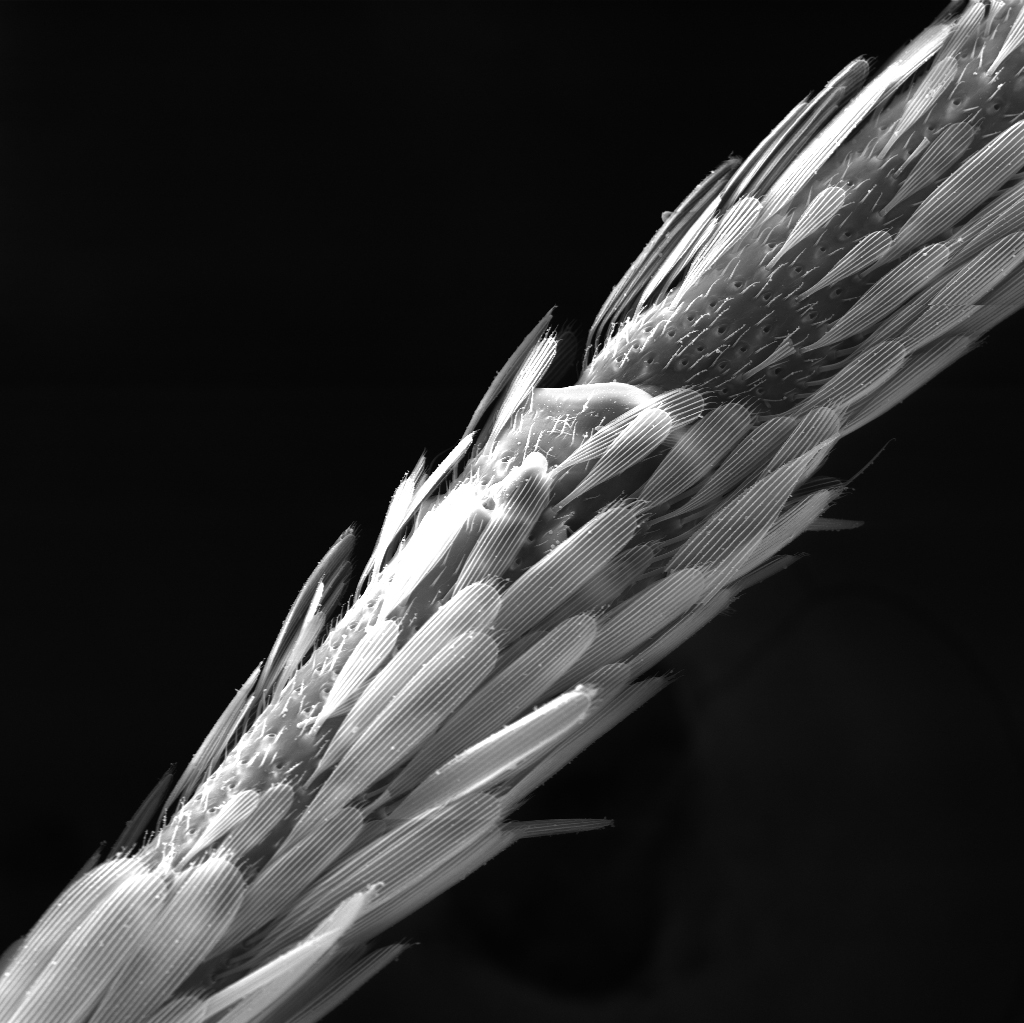

SEMs of fabrics before/after washing, either coated or uncoated. Check out all that damage!

When apparel is laundered the rubbing of the fabric against other articles of clothing, or even the washing machine, causes the release of small 'microfibres' into the wash water. For synthetic garments these are microplastics, which are an environmental pollutant and take hundreds of years to degrade. The DREAM Lab developed a fabric finish that almost completely eliminates microplastic release from textiles by minimizing friction. Check out our work on nylon here. You can also find a highlight in Nature here, and a more detailed discussion in Nature Reviews Chemistry here.

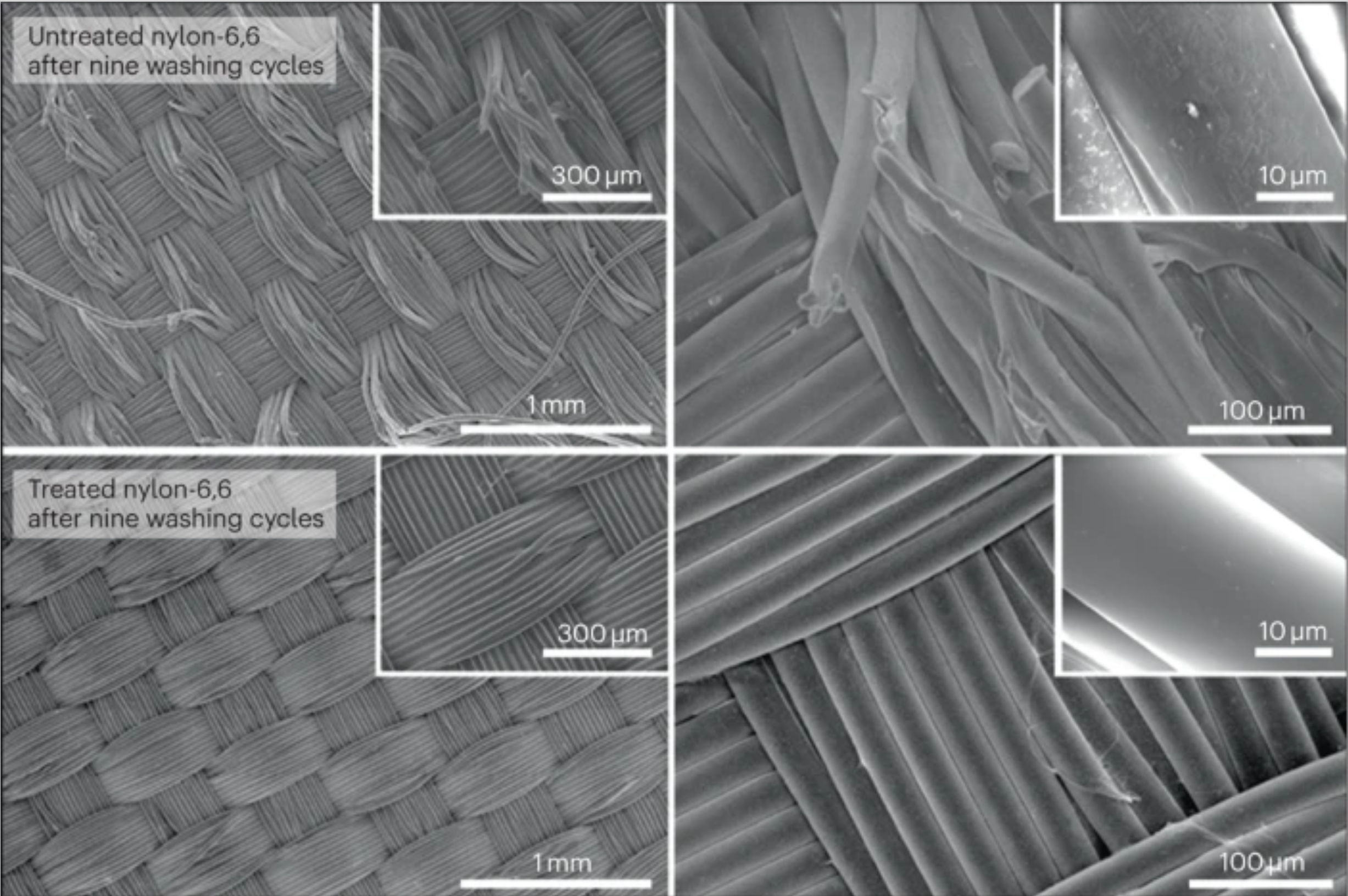

Optical image of the microfibres filtered from wash water that were released from uncoated nylon during laundering.

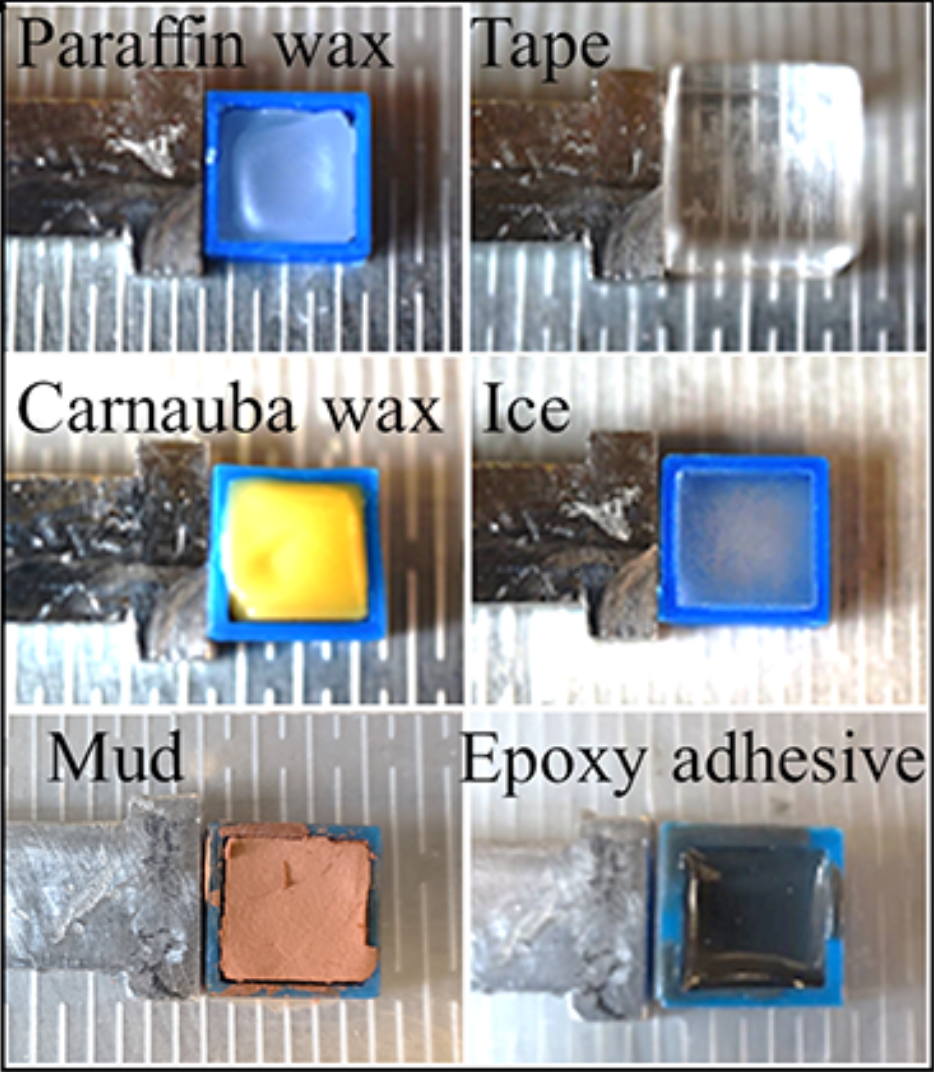

Durable Ice-phobic Surfaces

A full square meter of adhered ice – removed solely by gravity!

Ice accretion has a negative impact on critical infrastructure, as well as a range of commercial and residential activities. The DREAM Lab investigates new ways of understanding, controlling, and reducing ice accumulation. Back in 2016 we explained how interfacial cavitation, a surface instability, can be exploited to fabricate coatings with remarkably low ice adhesion. This also led to the development of ultra-durable icephobic materials. A year later we formulated a theoretical model to help explain another phenomenon that can reduce ice adhesion: interfacial slippage.

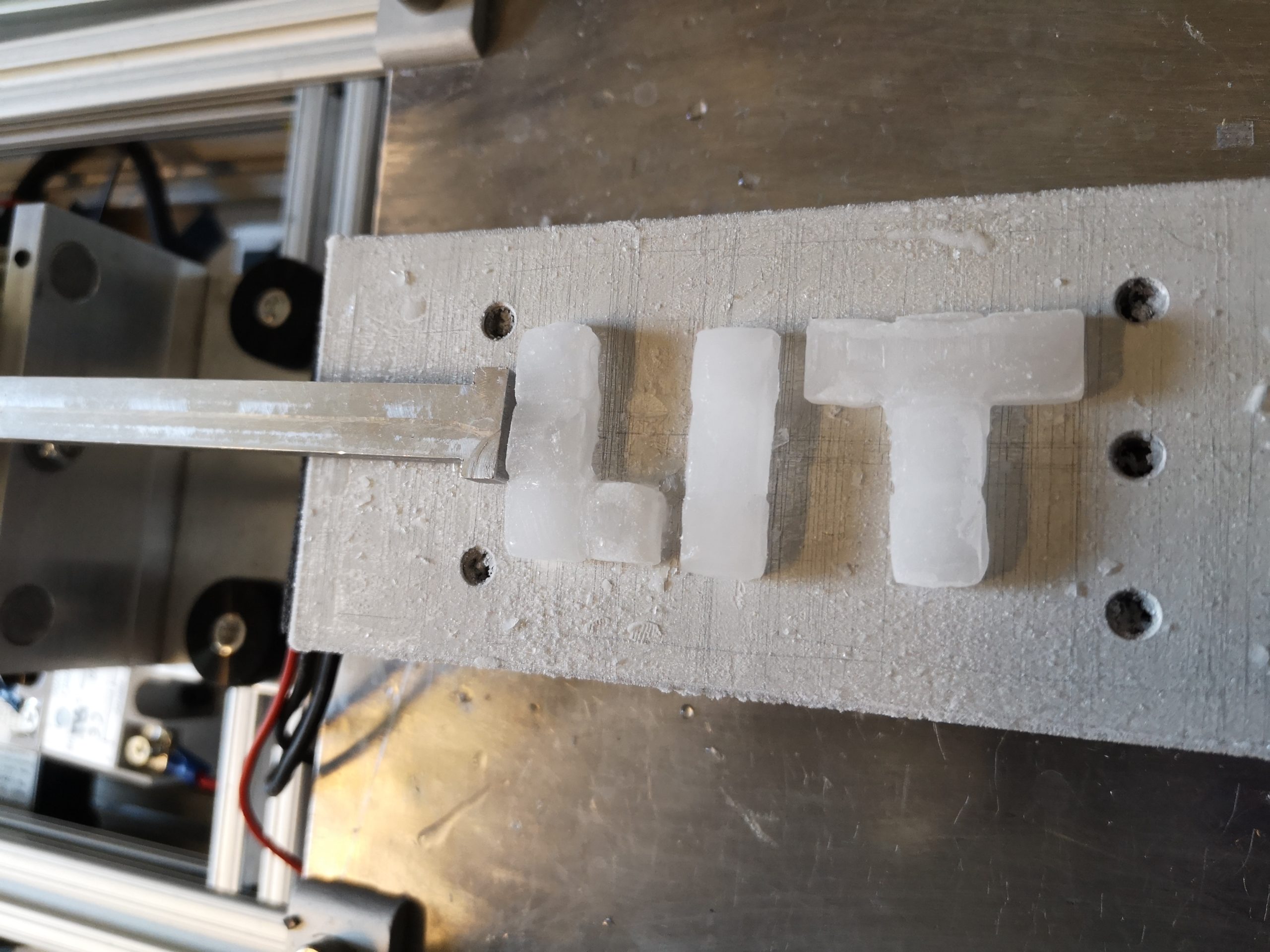

In 2019 we had a scientific breakthrough in terms of ice adhesion: the common metric everyone had previously used to characterize the bonding between a surface and ice, it's ice adhesion strength, was an incorrect, or at least incomplete, characterization tool. For interfaces larger than a few cm, ice fractures through crack propagation which does not depend on the ice adhesion strength, but rather the interfacial toughness. Our study explaining the mechanics behind this, as well as how to generate Low Interfacial Toughness (LIT) materials, was published in Science.

Fundamentals of Adhesion

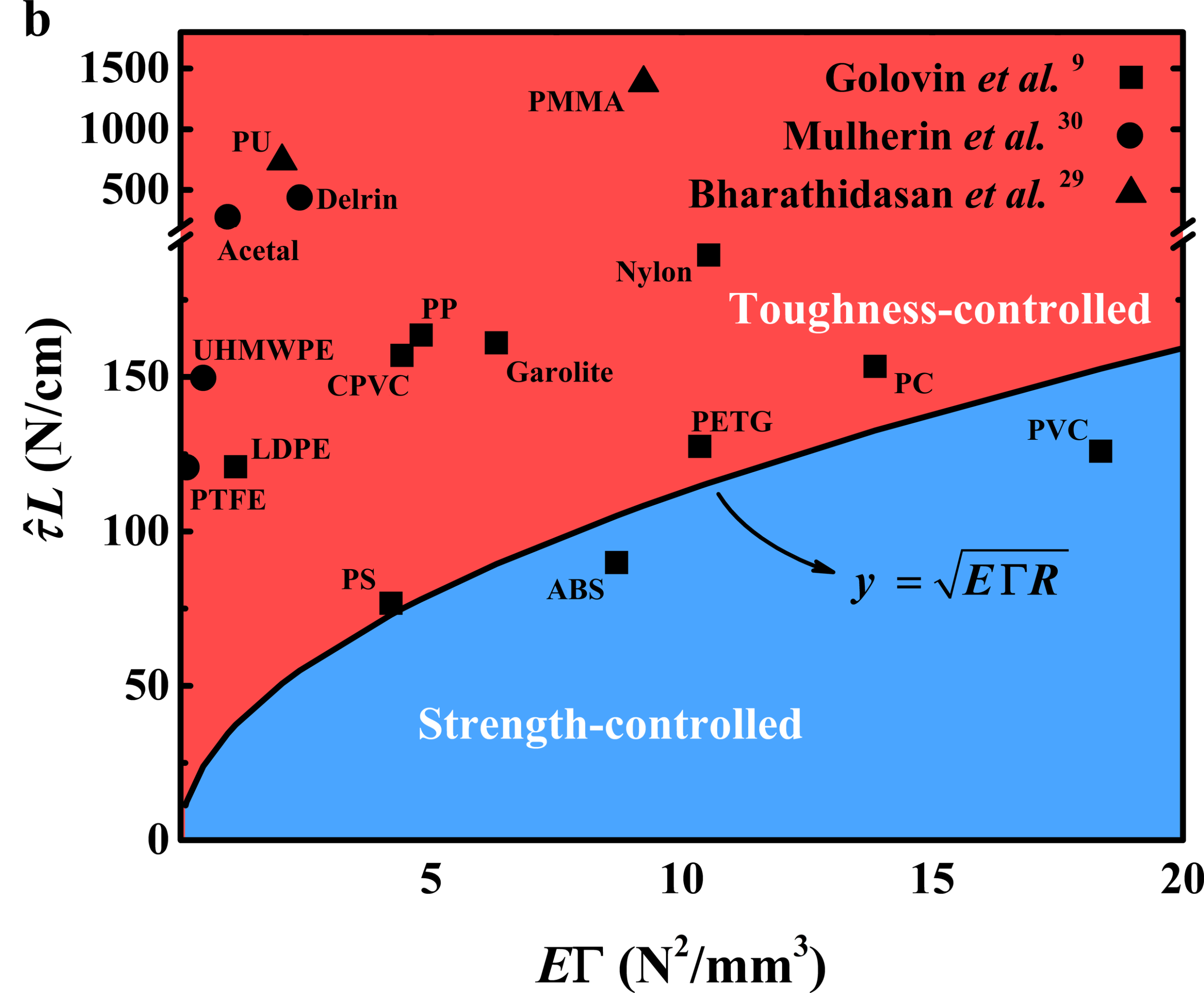

A fracture phase diagram showing that essentially all prior measurements of ice adhesion using the Zero-Degree-Cone-Test did not actually measure the shear strength of the interface.

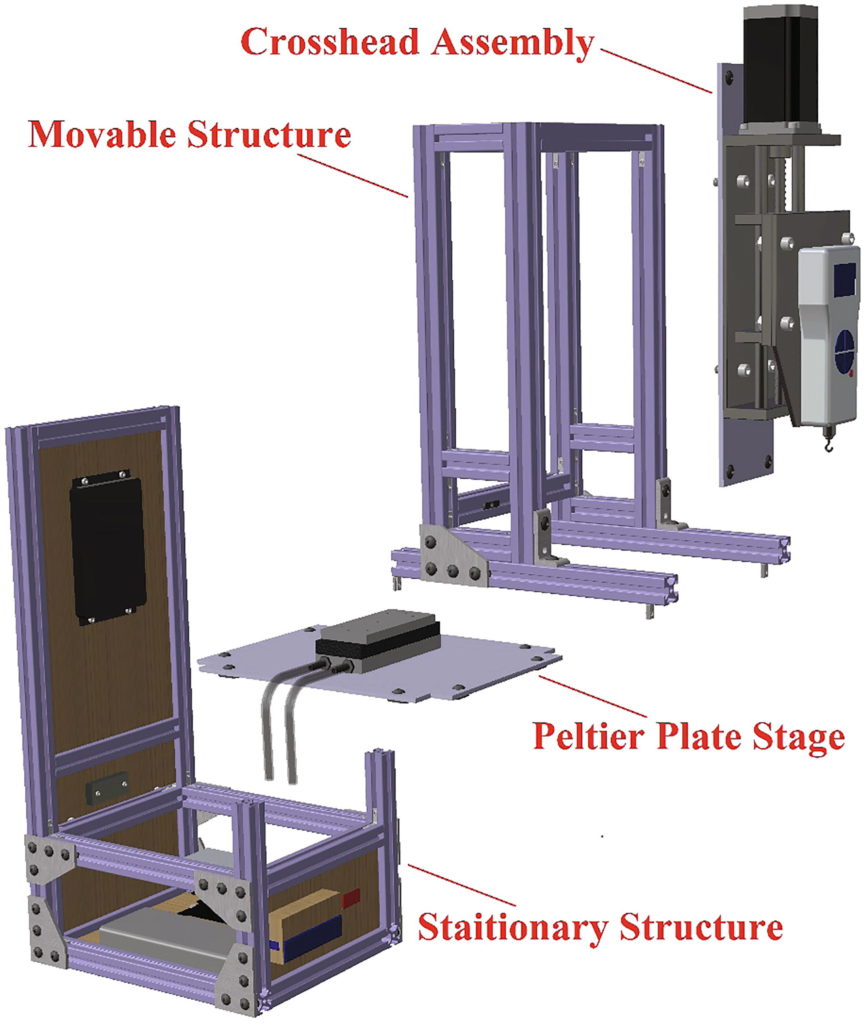

Ice adhesion testing is a complex and intricate measurement where a number of different variables must be considered. The DREAM Lab also investigates new and correct ways of accurately measuring ice adhesion, including developing measurement systems, understanding the fracture mechanics of ice delamination, and visualization of ice fracture.

Our high-throughput tensile ice adhesion measurement system allows for the rapid and accurate measurement of ice adhesion in tension, as opposed to the common measurement in shear. Understanding tensile ice adhesion is important as almost all delamination is mixed-mode fracture.

Interfacial cavitation is a surface buckling instability that may be exploited to lower the adhesion of fouling materials like ice. However, the complex dynamics of cavitation have not been adequately studied over large areas. The video to the right shows the imaging of a cavitating interface in real time, along with an "initial detachment" length - a previously unobserved phenomenon.

Cavitation bubbles and the initial detachment (green) for a foulant/silicone interface (magenta) during interfacial detachment

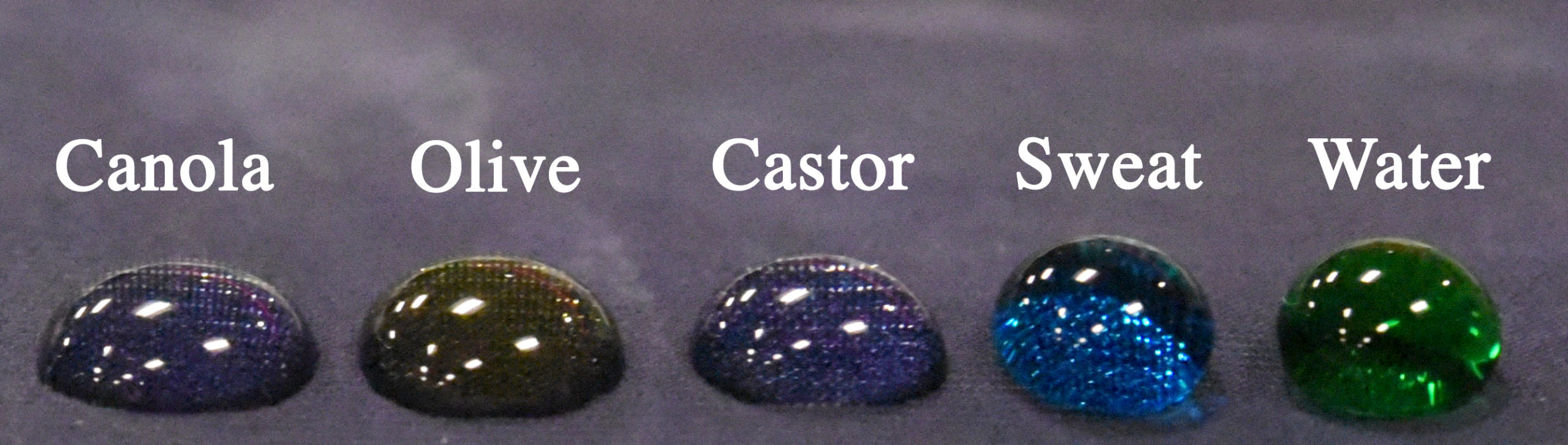

Fluorine-free Omniphobic Surfaces

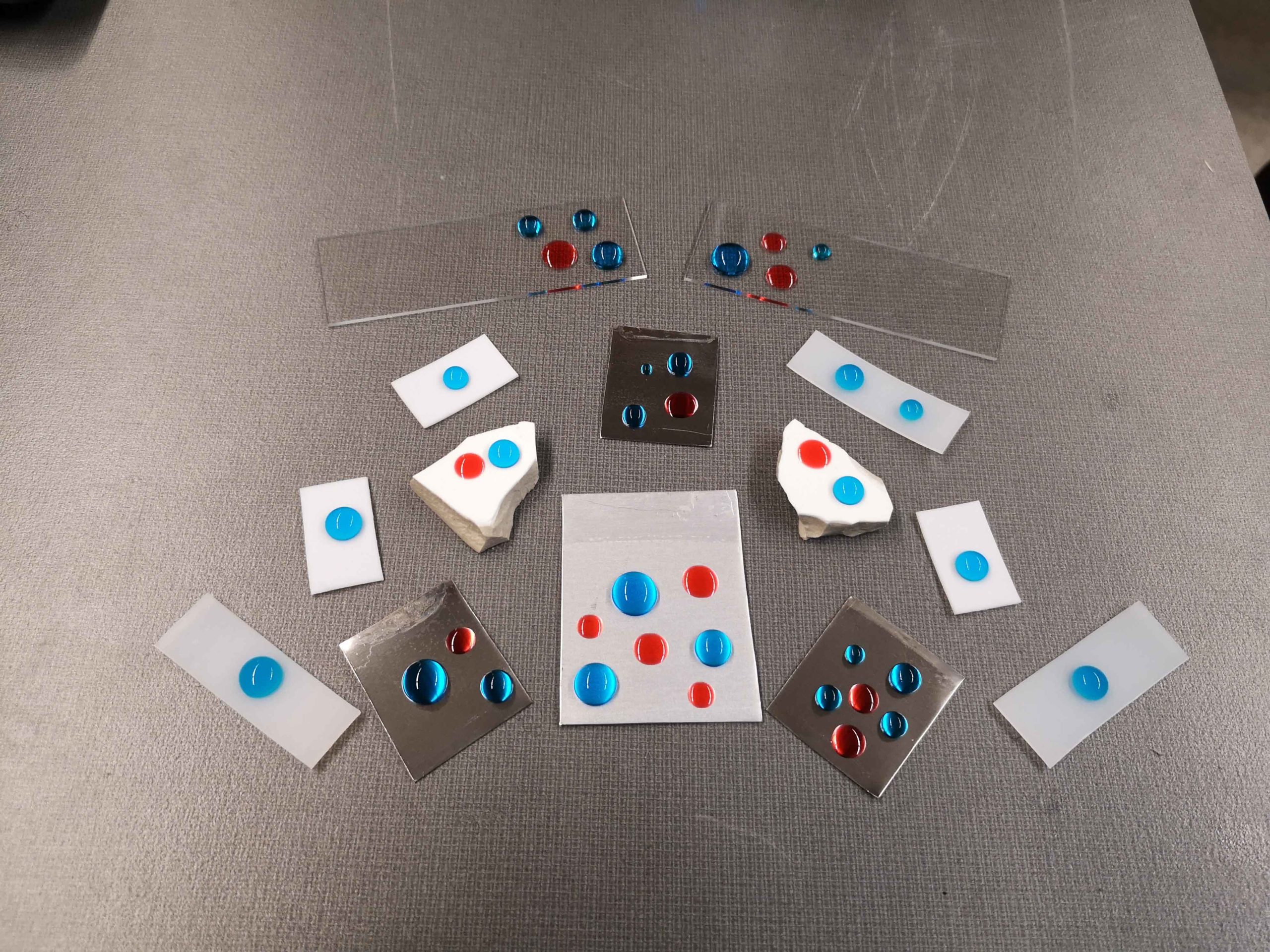

Our substrate-independent, omniphobic surfaces. Shown are glass, aluminum, steel, ceramic, paper, polyethylene, and polypropylene all rendered omniphobic. Water is dyed blue and hexadecane is dyed red.

Coatings repellent to many different liquids, including hazardous and low-surface-tension liquids like oils and alcohols, are termed omniphobic. Traditionally all omniphobic surfaces required PerFluoro-Compounds (PFCs), but these have been shown to be toxic and were banned in 2015 by the EPA. At UBCO we are pioneering a new generation of PFC-free omniphobic surfaces that can be applied to any substrate.

Our Silicon Wafer-like Omniphobic Liquid Layer (SWOLL) coating, applied to rough Aluminum and displaying extreme liquid repellency. The surface roughness could not diminish our omniphobic properties. Get SWOLL (coatings)!

The world's first PFC-free textile that can repel oils!

Waterproof jackets around the world fall into two categories: those that repel oils, and those that are PFC-free. We're fighting that limitation by developing the first PFC-free, oil-repellent textile finishes. And we're not alone. With help from Arc'teryx, lululemon, and the DND, hopefully together we can crack with worldwide issue! In 2020 we published the first report of a textile that could repel oils without the use of PFCs.

Comparison between a typical release liner (silicconized paper) and our nano-PdMS coating technology. Above is the TAPPI Kit test Liquid #12 (the most difficult liquid to repel)

PFCs are common in the pulp and paper industry where oil and grease resistance (OGR) are required. The DREAM Lab is developing PFC-free coating technologies for the paper industry that offer the same level of OGR. The materials are additionally being developed to be recyclable and applied using the same technologies currently used in the pulp and paper industry.

Ethanol, olive oil, and water being repelled by the nano-PDMS paper after 48 hours. Perhaps wellplates could be replaced by disposable paper in the future.

Turbulent Drag Reduction

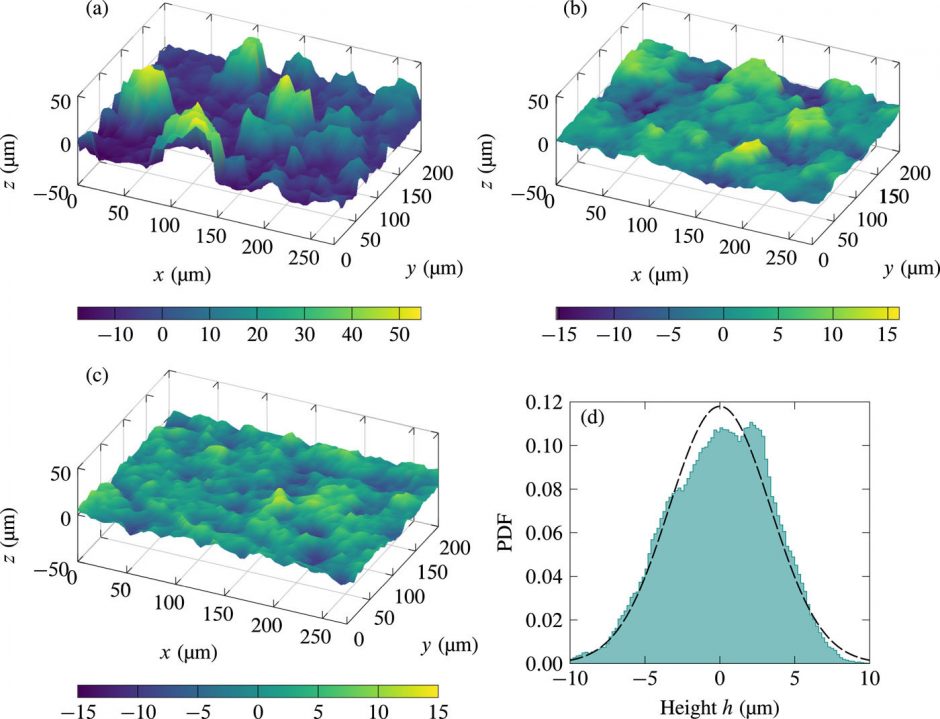

Plastron imaging and heightmap analysis of a rough, superhydrophobic surface for turbulent drag reduction

The entrainment of air within the porous texture of liquid-repellent surfaces enables them to alter the hydrodynamic properties of the surface, notably skin friction. By creating a shear-free interface the drag on a surface can be significantly reduced through the application of a coating. The DREAM Lab is working to make these coatings robust and long-lasting so that marine vessels can maximize their fuel efficiency in our oceans.

A liquid-repellent sphere entraining air as it enters a column of liquid.

Anti-Mosquito Surfaces

Comparison between ping pong balls painted with regular paint and our anti-mosquito paint.

The DREAM Lab collaborates with Loop Recycled Products (Niagara, ON) on the development of anti-mosquito paints. Unlike traditional toxic compounds, the anti-mosquito paint we're developing is a spatial repellent - mosquitos won't land on the surfaces but won't be killed by it either. This strategy avoids the issue of insecticide resistance, in addition to being non-toxic to humans. Our goal is to help curtail malaria, zika, dengue, yellow fever, and chikungunya worldwide!

The leg of an aegis egypti mosquito leg at 1000X magnification.

Advanced Sensors

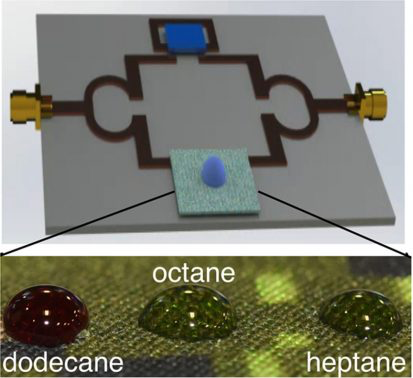

An array of split-ring microwave resonators mounted on a kirigami sheet, to be used as a high-accuracy strain sensor.

The DREAM Lab collaborates extensively with the OMEGA Lab at UBC, towards the development of novel sensors and sensing platforms for a range of engineering scenarios. The novel combination of repellent coatings and non-contact sensors enablels a host of new sensing applications for aerospace, composites, structural health monitoring, and even PPE.

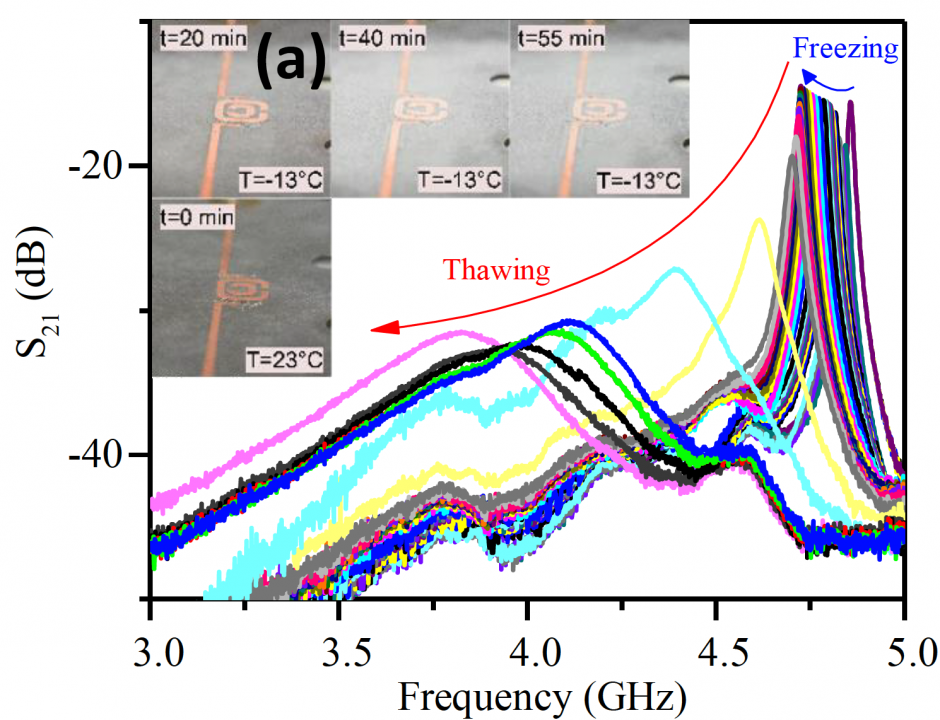

Sensing the freezing and melting of a droplet of water, enabling the real-time detection of ice and snow accretion on surfaces like airplane wings or wind turbine blades

Detection of oil repellency in real time, for hazard detection when embedded in Personal Protective Equipment (PPE)

An embedded miccrowave resonator sensor underneath two fabrics: one with our repellent coating and one without. When the coating is absent the sensor cannot function because the liquid destoys the microwave response of the structure.

Anti-icing + de-icing + detection on a single surface, enabled by a superhydrophobic coating, a patterned ground heater, and a microwave resonator sensor

Droplet Mechanics

Passive, guided transport of low surface tension liquids

The DREAM Lab investigates many fundamental aspects of liquid droplets, including impact, transport, wettability theory, and phase changes. Knowledge on these basic topics is applicable to a wide range of engineering applications, including moisture management systems, delaying ice freezing, and designing next-generation liquid-repellent coatings.

A water droplet impacting a highly liquid-repellent surface

Kirigami Surfaces

Watch the fascinating phenomenon of a kirigami sheet wrinkling as an adhered foulant is sheared from its surface, by exploiting the photoelasticity of cellulose acetate

The DREAM Lab is interested in surfaces that don't act quite like normal materials do. The Japanese art of paper cutting, kirigami, is one such class of surface that is auxetic (expands upon compression) and has very interesting surface properties, particularly when wrapped over a surface like a conformal coating.